The most commonly asked question is ‘What is Diecutting / Die Cutting?’ Although describing diecutting is not particularly difficult it is useful to put this high volume manufacturing process into the context of Converting. Diecutting is a Converting Process, which generally uses six toolmaking disciplines to Cut, Crease, Score, Perforate, Deboss or Emboss a substrate or a web or sheet of material. Diecutting is the process, which uses a combination of tools to ‘convert’ a material into a product, part or component of higher value than the original material.

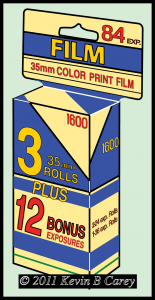

The most commonly asked question is ‘What is Diecutting / Die Cutting?’ Although describing diecutting is not particularly difficult it is useful to put this high volume manufacturing process into the context of Converting. Diecutting is a Converting Process, which generally uses six toolmaking disciplines to Cut, Crease, Score, Perforate, Deboss or Emboss a substrate or a web or sheet of material. Diecutting is the process, which uses a combination of tools to ‘convert’ a material into a product, part or component of higher value than the original material. In most diecutting applications the sheet or web of material to be processed is pre-printed on one or more sides to provide information in the form of text or graphic brand identification, and a description and instructions of how to use the component or the contents of the finished container. See right.

In most diecutting applications the sheet or web of material to be processed is pre-printed on one or more sides to provide information in the form of text or graphic brand identification, and a description and instructions of how to use the component or the contents of the finished container. See right. This is important to the platen diecutting process as the image on the sheet material must precisely register to the male and female platen press tooling if the final product is to be consistent with the approved prototype.

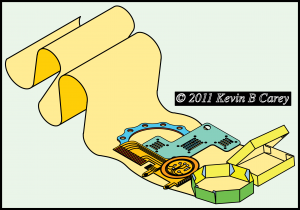

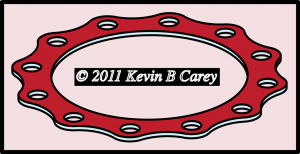

This is important to the platen diecutting process as the image on the sheet material must precisely register to the male and female platen press tooling if the final product is to be consistent with the approved prototype.With the graphic elements of the work complete the printed substrate is ready for the converting process. One element of converting is the permanent transformation of the two dimensional image into a shape which can be formed into a three dimensional container, see left,

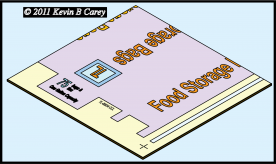

or a two dimensional product such as a display card, gasket, or an industrial component. See right.

or a two dimensional product such as a display card, gasket, or an industrial component. See right.This is where the finished product first emerges and it is a critical first test of the marriage between the graphic image and the structural concept. For example to create a folding carton design a paperboard sheet may require one or more of the six basic diecutting or converting processes to generate the product.

As you can see from the gasket illustrated above there are other critical disciplines in diecutting, which impact the efficiency of the process. These would include automatically removing the wast material and slugs from the diecut product, called Stripping, and the automatic stacking of the finished products, called Blanking.

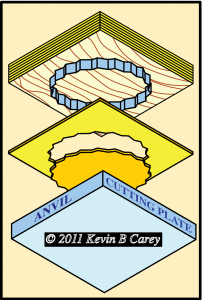

As you can see from the gasket illustrated above there are other critical disciplines in diecutting, which impact the efficiency of the process. These would include automatically removing the wast material and slugs from the diecut product, called Stripping, and the automatic stacking of the finished products, called Blanking.The converting disciplines are Cutting, see left, or the separation of a sheet or web of material into individual parts, compoenents or finished products. This shows the platen diecutting process in which the material is trapped between an upper steel rule die and a lower cutting anvil or plate.

For many diecutting operations Cutting would comprise the entire process. However, when converting other prodcuts, particularly folding cartons and fluted containers, the diecut part will be folded and erected into a three diemensional container, or Point-of-Purchase display device, often with key graphics printed on the surface. Therefore, to create this type of finished product it is often necessary to integrate the other five converting disciplines.

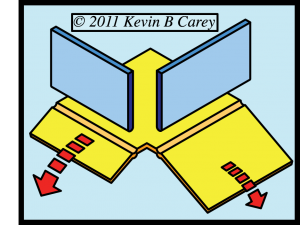

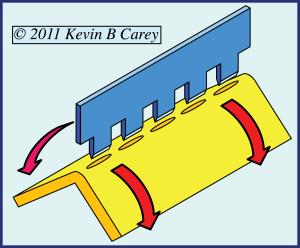

For many diecutting operations Cutting would comprise the entire process. However, when converting other prodcuts, particularly folding cartons and fluted containers, the diecut part will be folded and erected into a three diemensional container, or Point-of-Purchase display device, often with key graphics printed on the surface. Therefore, to create this type of finished product it is often necessary to integrate the other five converting disciplines.Converting Creasing, see above right, is the generation of a controlled failure of the material, by creating a hinge point in the material, which will enable the material to fold through 180 degrees without the ma-

terial, and particularly the outer surface of the material from splitting or cracking.

terial, and particularly the outer surface of the material from splitting or cracking.When creasing, the combination of a male tool inserted into the steel rule die and a matched female tool mounted on the cutting plate enable the generation of internal delamination stress failure in paperboard and the crush/deformation of a fluted material. Both of which enable the material to hinge and fold.

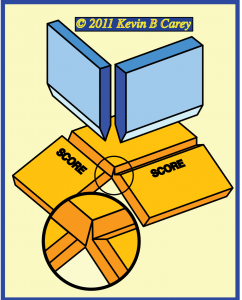

Converting Scoring, see left, is often used to achieve a similar type of controlled failure in the substrate/design, however, instead of a blunt round topped crease rule, scoring is achieved with an identical, but lower height cutting knife. This enables the partial penetration or partial cutting of the material, usually to enable a sharp, precise fold or failure point.

Similar to cutting, Converting Perforating, see right, uses a cutting knife to penetrate the material, however, the cutting edge of the knife has gaps machined into it to create individual ‘teeth.’ In a ‘folding’ application this has many uses, and employs many different patterns of ‘tooth-gap’ to achieve a skip cut to provide a weaker square fold or a specific degree of folding force. However, Perforating knife is not just limited to creating folds in a substrate and is used in many converting applications and is a very versatile tool.

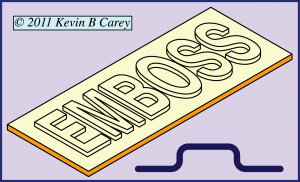

Similar to cutting, Converting Perforating, see right, uses a cutting knife to penetrate the material, however, the cutting edge of the knife has gaps machined into it to create individual ‘teeth.’ In a ‘folding’ application this has many uses, and employs many different patterns of ‘tooth-gap’ to achieve a skip cut to provide a weaker square fold or a specific degree of folding force. However, Perforating knife is not just limited to creating folds in a substrate and is used in many converting applications and is a very versatile tool. Converting Embossing, see left, is a process where a section of the material is permanently deformed into a relief shape above the printed surface to enhance an image or to highlight a design feature. Embossing is generally employed to enhance the ‘look’ and perceived value of the product, enclosed in the embossed container. Because Embossing often requires considerable pressure, and heat, when utilizing a ‘foil-stamping’ process, it is often completed in advance of diecutting, however, it is also often simultaneously combined into the diecutting process.

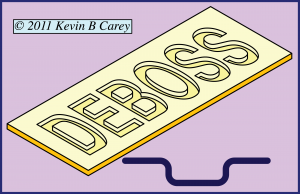

Converting Embossing, see left, is a process where a section of the material is permanently deformed into a relief shape above the printed surface to enhance an image or to highlight a design feature. Embossing is generally employed to enhance the ‘look’ and perceived value of the product, enclosed in the embossed container. Because Embossing often requires considerable pressure, and heat, when utilizing a ‘foil-stamping’ process, it is often completed in advance of diecutting, however, it is also often simultaneously combined into the diecutting process. Converting Debossing, see right, is the opposite of embossing, in that the material is depressed below the remaining surface of the substrate. Debossing has multiple applications but is generally associated with deforming the material to create a better assembly and gluing process for folding carton and container manufacturing.

Converting Debossing, see right, is the opposite of embossing, in that the material is depressed below the remaining surface of the substrate. Debossing has multiple applications but is generally associated with deforming the material to create a better assembly and gluing process for folding carton and container manufacturing.Diecutting or Die Cutting consists of the integration and mixing of these six disciplines to provide the Convertor with an extraordinary range of manufacturing options. This simplicity, when combined with the diversity of design options is why Converting is one of the most important processes in any industrialized society.

Source : Die-CuttingWorks