By : Kevin Carey

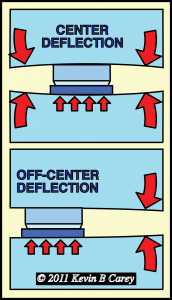

One of the hidden challenges facing the diemaker and the diecutter, is the deflection and distortion of the diecutting press under the considerable force required to convert a substrate into quality products with consistent performance attributes. The degree of deflection is related to the size of the steel rule die design/layout compared to the size of the press, see above right, and the location of the die, compared to the center of effort of the mechanism. This is often characterized as Center Deflection and/or Off-Center Deflection. See above left. Obviously the primary difference in location is based upon if the press is either a gripper fed substrate system or a conveyor fed substrate system.

One of the hidden challenges facing the diemaker and the diecutter, is the deflection and distortion of the diecutting press under the considerable force required to convert a substrate into quality products with consistent performance attributes. The degree of deflection is related to the size of the steel rule die design/layout compared to the size of the press, see above right, and the location of the die, compared to the center of effort of the mechanism. This is often characterized as Center Deflection and/or Off-Center Deflection. See above left. Obviously the primary difference in location is based upon if the press is either a gripper fed substrate system or a conveyor fed substrate system.  To avoid the inevitable damage this would cause to the steel rule die, the press, and the diecut products the diemaker cooperates with the diecutter to modify the tools to incorporate balancing devices. These include the use of Press Stops, see right, integrated into the periphery of the steel rule die, and designed to ensure the reciprocating platen can only close to a specific gap, between the upper and lower surfaces.

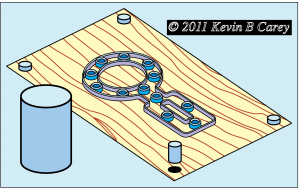

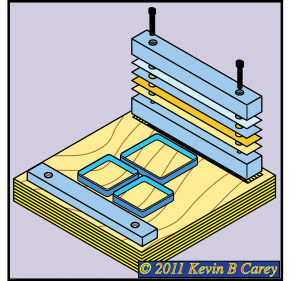

To avoid the inevitable damage this would cause to the steel rule die, the press, and the diecut products the diemaker cooperates with the diecutter to modify the tools to incorporate balancing devices. These include the use of Press Stops, see right, integrated into the periphery of the steel rule die, and designed to ensure the reciprocating platen can only close to a specific gap, between the upper and lower surfaces. A similar technique requires the integration of ‘Bearers’ into the periphery of the layout. These can be a fixed height, similar to the press stops, or they can include the ability to add or remove several adjustment ‘shims.’ See left. A common alternative to using press stops and bearers is the use of the same height cutting knife, see right, to act as a press stop or a bearer, and limit the deflection or distortion of the platen mechanism.

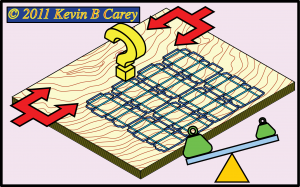

A similar technique requires the integration of ‘Bearers’ into the periphery of the layout. These can be a fixed height, similar to the press stops, or they can include the ability to add or remove several adjustment ‘shims.’ See left. A common alternative to using press stops and bearers is the use of the same height cutting knife, see right, to act as a press stop or a bearer, and limit the deflection or distortion of the platen mechanism.The theory is, and it is important to state up front that the assumptions made are fatally flawed and are incorrect, that using the same standard height cutting knife used in the die for the bearer knives, the inevitable compressive damage to the cutting knives in the steel rule die, would be matched by identical compressive damage in the bearer knives, so balance across the entire platen would be maintained. However, this makes dangerous and incorrect assumptions.

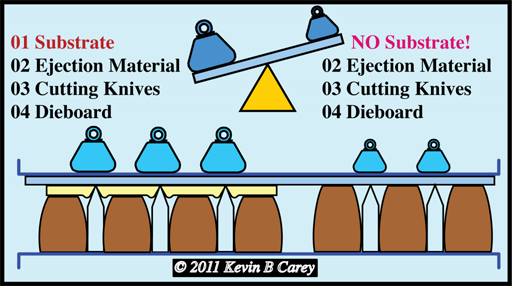

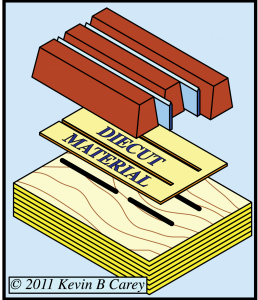

The assumption is the leveling knives will balance and stabilize the distribution of pressure to prevent press deflection and maintain a perfectly parallel relationship between the platen surfaces and the tools. Unfortunately, when you examine this theory in detail it makes little sense. In the diagram above you can see the stack of components centered on the steel rule die and the stack of components centered on the leveling knives … are not the same! What is missing is the thickness of substrate from the leveling knives! Therefore, this standard approach to using leveling knives has minimal impact on press leveling.

Even when the substrate is integrated into the leveling knife pattern, see right, we still have a serious imbalance. This is caused by the reality that the die is penetrating and bursting paperboard, which significantly increases the pressure or resistance generated by the die compared to the pressure/resistance generated by the leveling knives, which are not pinching and penetrating a substrate.

Even when the substrate is integrated into the leveling knife pattern, see right, we still have a serious imbalance. This is caused by the reality that the die is penetrating and bursting paperboard, which significantly increases the pressure or resistance generated by the die compared to the pressure/resistance generated by the leveling knives, which are not pinching and penetrating a substrate.The bottom line is inescapable. Using Leveling Knives in the standard manner is largely ineffective in balancing pressure across the cutting surface of the platen.

The solution is to combine Full Height Creasing Rule with ‘Power Ejection’ techniques. But more on that in another article…

Source : Die Cutting-Works