By : Kevin Carey

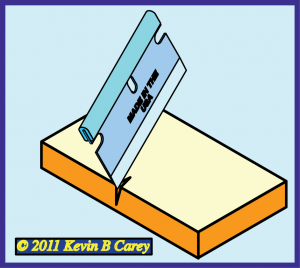

Simultaneous Diecutting is a somewhat illogical means of ‘die-cutting.’ For example, to cut a thin sheet of paperboard, rubber, or plastic the material is positioned upon an anvil or a flat plate and a razor blade would be a logical choice as an efficient cutting implement. However, instead of angling the blade to penetrate and then drawing it through the material as one would expect, see left, the entire knife edge of the blade is positioned against the surface of the material, see right, and then the upper edge of the blade ferule is struck with a hammer to drive it into and completely through the material! See below.

Simultaneous Diecutting is a somewhat illogical means of ‘die-cutting.’ For example, to cut a thin sheet of paperboard, rubber, or plastic the material is positioned upon an anvil or a flat plate and a razor blade would be a logical choice as an efficient cutting implement. However, instead of angling the blade to penetrate and then drawing it through the material as one would expect, see left, the entire knife edge of the blade is positioned against the surface of the material, see right, and then the upper edge of the blade ferule is struck with a hammer to drive it into and completely through the material! See below.This is hardly the image the average person would visualize if you described an efficient method of cutting a material! This type of cutting procedure is called a simultaneous cutting process because the entire cutting action takes place all at the same time. In other words every part of every cutting edge will strike to material at the same time and the material will be cut apart in a single pinching, bursting action. Clearly there are some technical disadvantages with this approach when compared to the incremental cutting process.

In incremental cutting only a small amount of the blade is used at any given time, however, in simultaneous cutting the entire length of the blade is used in a single impression. See right. This also clearly means the amount of pressure applied at any one time is much greater in the simultaneous process than the incremental process. See left.

In addition, as the entire cutting action of the simultaneous process is instantaneous any variation in caliper, density, hardness or fiber mix in a material will impair the cutting action. This is because when using the incremental slicing action, pressure is concentrated on a small point of the knife edge and a minute area of a material at any given moment, therefore, the impact these variables have on cutting efficiency is minimal. However, as simultaneous cutting happens all at the same time it is difficult to vary pressure selectively on different areas of the blade to compensate for material variation. See right.

Compounding the problem of simultaneous cutting is the plate or anvil the material is trapped against. See left. Obviously a hard material such as steel must be used so the repeated impressions of the razor blade do not wear a groove in the surface of the cutting plate, as when cutting onto a sacrificial cutting anvil/plastic compound which is designed to be damaged. See below.

However, if the blade strikes the plate with excessive force, see below left, because too much pressure was used or the material being diecut was softer than expected, the knife cutting edge or tip would be compressed, swaged and damaged. See below right.

Therefore, a great question to ask is … If Incremental Cutting is much more efficient than Simultaneous Cutting why is Platen Diecutting the dominant volume manufacturing technology? To understand how the application of these different methods of cutting is applied to production diecutting it is useful to examine the alternative diecutting technologies and determine how the principles and practices of each system of diecutting can in fact, compliment each other.

A comprehensive understanding of how Simultaneous Processing works and Incremental Processing works, and to have the ability to integrate each into the other process is an essential skill in achieving productive success in diecutting.